One of the advantages that the people of Grantville have in the novels 1632 and 1633 is their technology. With their tools, the people of Grantville can turn out cannon, rifles, and steam engines. With their chemical knowledge, they can create antibiotics, aspirin, and DDT. With their electronics, they can create diplomatic and broadcast radios. Everything's a piece of cake, right?

Everything is very far from a piece of cake. After making many cannon, the cutting edges of their machine tools will be worn out. There is no Hi-SpeedTM tool steel in the 1630s. It wasn't even invented until the late 1890s. In order to keep a cutting edge, the people of Grantville need some form of tool steel. Early tool steels contained iron, tungsten, and a small amount of carbon. Better tool steels also contain chromium and vanadium, and even more tungsten. Tungsten, chromium, and vanadium weren't known in the 1630s. The people of Grantville have no easy way of purchasing them.

Things get worse. In order to make pharmaceuticals, the people of Grantville need stainless steel, or glass-lined vessels. To make stainless steel, they will need chromium, nickel, and perhaps vanadium. Nickel wasn't known in the 1630s. (Yes, nickel ore was known. So were the ores for zinc and tungsten. The metals weren't known. More about those later.) For the proper glass, they will need borates. Borates were imported from Turkey and Italy.

There are many strategic minerals for Grantville that are necessary to gear down up-timer technology. Grantville has not brought the idea of strategic minerals to the seventeenth century, however. Already people are making a fortune in the creation of war-related brass and bronze. Gunpowder production was a booming industry.

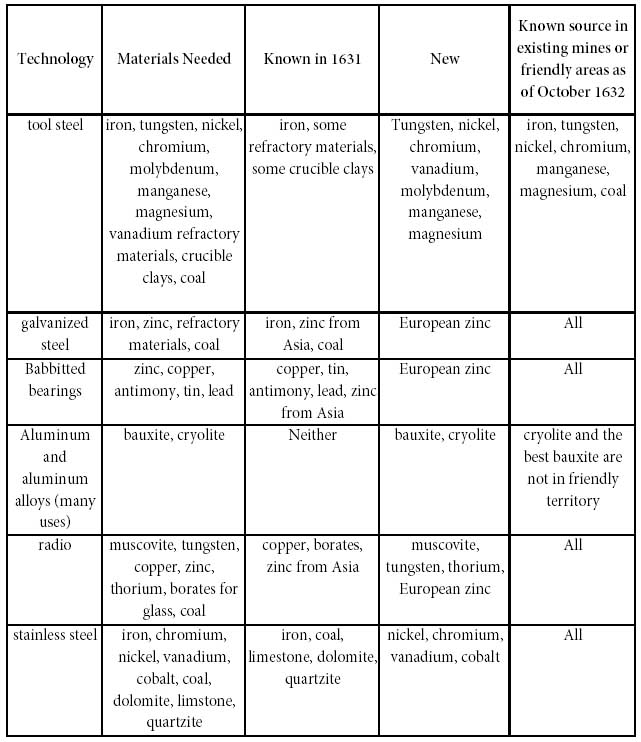

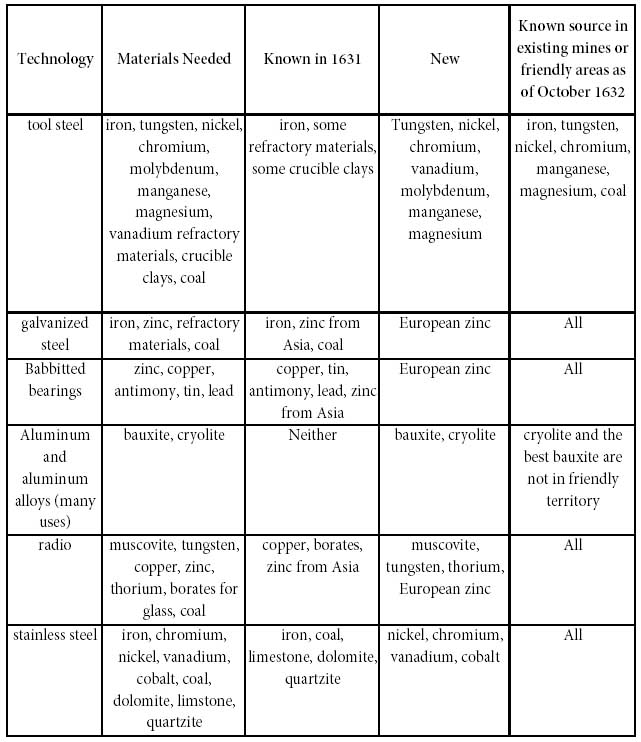

The table below shows some of the resource needs to gear down Grantville's technology.

Even though this is a complex problem, the answer seems simple. Get out a CD-ROM atlas of the world, and search for needed minerals in or near Germany. If there isn't a CD-ROM atlas, look up mining sources for each of these metals. Then find maps of the places in a paper atlas, and start mining the material.

The problem comes down to three things: the politics of mining, the economics of mining, and the technical parts of geological surveying. Each of these will be covered in a section of this article.

There aren't enough up-timers to send out on the search. Only a few up-timers could be trained and sent out on surveys. No up-timers have all the needed skills. The last part of this article will deal with the role of the up-timers as they work with down-timers to obtain strategic minerals.

It's important to remember that Grantville didn't appear in a vacuum. Germany had been mined for a very long time by 1632. Political structures, bureaucracies, and economies had already been built around mining. Some important resources aren't in friendly areas right now. Cryolite is found only in Greenland, a province of Denmark, which is at war with Grantville. A middling good ore of bauxite is at Vogelsberg, within striking distance of Duke Bernhard. It's very hard to start a mine in a war zone. But even outside of a war zone, there are problems with just walking up and digging.

Mining law is complex stuff. Seventeenth-century European mining laws differ from up-timer mining law. The most important variations in Germany were not from place to place, but from product to product. The up-timers don't just have to deal with a different set of rules—they need to remember variations on these rules for different products and different areas.

In Germany, the status of mineral ownership depended heavily on the sort of the mineral. The emperors gave rights, which were often theoretical, to sovereigns of all sort (rulers, abbeys, towns, and so on) in the Middle Ages. But these rights didn't include all minerals. Only silver, gold, lead, copper, tin, and salt followed the strict rules.

Other mineral resources (iron, coal, hard rock, sand, clay, etc.) usually belonged to the landowner. Usually. In some parts of Germany sovereigns claimed ownership for all minerals. These claims were only partly successful in the first half of the seventeenth century. However (mining law is complex), iron was sometimes treated as a valued metal if it was high-quality hard ore that was mined, rather than quarried.

In general, permission was needed to prospect for minerals. More permission was needed for mining, and for using nearby wood and water. Permission for prospecting came from the landowner. The permission for mining valued minerals came from the ruler and/or the mining administration of the area. Base minerals were mostly considered the landowner's property, and could be mined without much trouble from a mining administration.

In practice, if the prospector or mine operator showed that they had enough money and people to carry out the mining in an orderly fashion, permission was almost always granted. A mine was a source of free royalties to the ruler of the territory. The landlord usually got one or more shares, and these shares sometimes had some special privileges. Claim sizes were pretty standard, but there was some variation by the resource.

The way mine ventures were organized is beyond the scope of this paper. They weren't organized in the same manner as shipping companies, although shares were bought and sold. The thing to remember is that share owners also had to pay ongoing operating expenses if the mine was not able to make a profit. Think of owning a share in one of these ventures as a game of financial chicken.

Mine operators needed to pay out shares and royalties. Royalties were paid out with money or with a portion of the ore. If royalties were paid with ore, every tenth or so standardized basket of ore was set aside for the ruler. Shares were usually paid out to owners on a quarterly basis with money. Miners were sometimes the owners of shares or part shares, and sometimes the employees of the mine operator, or both. Owners paid for work that needed to be done on the mine, even if the mine had not brought in a profit. Even though rulers received royalties, they did not pay mine expenses, unless they acted as mine operators as well, or were shareholders.

Timber for supports, smelting, and machinery had to be purchased from the local holders of wood rights. In many places, part of the mining profits were set aside for the support of churches and charities. Unless the church or charity was acting as the mine operator, it did not need to pay expenses.

Mine claims had to be worked. In some cases, mining claims were leases for three to ten years. In most cases, they were perpetual leases, as long as mining lasted. If mining ceased for a period of time, the mine claim was forfeit. That was usually not a problem. (As long as two or more miners were working, the mine would be working legally and could not be forfeit.) If the district mine administrator requested that a mine improve its drainage or ventilation, and some effort was not made for improvement, the mine operator was fined. In some places, the mine was forfeit, and could be mined by another operator. In practice, if a mine was taking money out of the pockets of the mine operator, rather than making profits, the owners had to subsidize the mine.

Rules existed for mines. By 1632, there had already been several notable mining disasters. Usually the resulting rules did not involve the safety of individual miners, but rather the safety of the whole mine—drainage, ventilation, and the placement of tunnels and shafts.

There were environmental laws for the users of wood rights and for smelters. Mostly these laws involved the harvest of trees and the use of water. Water rights were even more complicated in heavily mined districts. Deforestation was a risk near the larger mines and an ever-present danger near the smelting ovens. Before the up-timers go in and try to create a mining bureaucracy, they need to remember that bureaucracies and mining consortiums already exist under the aegis of each local ruler.

Even with those rules, mining was a hard, dirty, and very dangerous job. It still is today. There are very few civilian jobs with a greater risk to health and life than underground mining. Even the best drainage and ventilation of the time was not always good enough. Because the miners used open flames (candles or oil lamps with reflectors), pockets of methane gas sometimes caused explosions. Other times, they just suffocated the miners. In the lead and silver mines, arsenic poisoning was sometimes a risk.

The Knappschaft, or miners' guild, was different from many other guilds in the seventeenth century. All miners, not just the master miners, belonged to the Knappschaft. There were miners' strikes, and mining law was changed to accommodate some demands of the miners. The Knappschaft also paid for the construction of a chapel for before-shift prayer outside most mines, and paid for charities for the members and families. The Knappschaft was not a modern miners' union, but the reactions of down-timer miners to the UMWA will be filtered through their experience with their local Knappschaft.

A mine is a hole in the ground that sucks up money. The world is full of abandoned mines that someone once felt worth starting. The greatest reason that mines are abandoned is that they don't pay enough to cover expenses.

The mines in the twentieth-century CD-ROMs and atlases are mines that are profitable using twentieth-century techniques for mining, ore dressing, and smelting. With a few notable exceptions, the mines in the oldest encyclopedias in the Ring of Fire were mines that were profitable using nineteenth-century techniques and transportation. Many of these mines could not be profitable with seventeenth-century mining, milling, and transportation. They might not be profitable after high explosives have been developed, and sometimes even after steam engines are available. Someone will need to survey the areas around known sources of the strategic materials to see if it is feasible to mine them.

Factors beyond the ore are important for mining profit. An ore body would have to be unbelievably good if all of the other factors were bad. These factors include ventilation and drainage, energy for ore dressing and smelting, refractory material for smelting, and transportation at several different stages of the process.

The difference between prospecting and mineral surveying is that prospecting only takes the ore body into account. Mineral surveying takes all of the factors for the mine into account. Down-timers already knew this. The silver ore near Joachimsthal was so good that it was profitably mined, even with lots of disadvantages. Some of the ores in the Harz mountains were not so rich, and wood and water were much bigger considerations.

The ore body itself is an important part of any equation. What mineral is being searched for? How close is the ore body to the surface? If it is not directly at the surface, what type of overburden exists? Would a strip or open mine work? Would a (very expensive) underground mine be needed?

Every mine needs ventilation and drainage. Open quarries and strip mines have built-in ventilation, but they still need to be drained. Underground mines often need long ventilation shafts and drainage tunnels, which are very time consuming and costly to create. Water- and wind-powered drainage and ventilation pumps are less expensive to operate than animal- or human-powered pumps, but they depend on the location of the mine, and on the weather. Water- and wind-powered pumps need cooperative weather and climate.

Ore dressing separates the ore from unwanted minerals and rocks. It can be done with hammers, mills, washing, cradles, or other methods. Smelting melts and purifies the ore. Energy for ore dressing and smelting is a must, and it needs to be convenient to the mine, unless the ore is extremely rich. In the seventeenth century, ore dressing was most often done with a combination of water-powered hammer mills, water mills, hand mills with hard-rock millstones, and vigorous washing. Smelting was done with hard coal, charcoal, peat, or wood. In a drought, such as Europe had in the summer of 2003, water power would not be available for many mining tasks. Ore dressing, ore transportation, and drainage pumping would need to be done by gravity, animal power, or human power. All of these are more expensive than water power.

The heat needed to melt many ores and refine them can be quite high. Any smelter needs to be lined with stuff that can take this heat. This heat-tolerant lining is called refractory material or lining. The type of refractory material for smelting can be important. Steel made with one refractory lining is different from steel made with another refractory lining, for instance. Because refractory materials are just a special type of building material, they need to be easily quarried and transported. A convenient means of getting refractory material to the smelter is important.

In the twenty-first century, it's hard to imagine how difficult and expensive transportation was in the seventeenth century. Today, Europe has an excellent network of roads, canals, and railroads, created at great cost over the last few hundred years. These are set up to handle vast amounts of freight, and the shipping cost does not add large amounts to the cost of goods.

Transportation in the seventeenth century was horrible. There's a reason large cities were either on seaports or on rivers that could be navigated with barges. Many of the roads in Germany were muddy or rocky. The distance that a wagon could travel was limited by the strength of the animals pulling it. The transportation costs for wood and peat usually doubled the cost for townspeople not too far from the source. For some goods, customs duties and taxes alone doubled the price. Rocks are heavy, and so even more expensive to ship.

The most economical mines had either gravity-based transportation or river-based transportation close to the mine. Some mines in the Harz and the Erzgebirge already had very well-organized networks of horse carts. They also used water power to lift the ore and rocks out of the mine. Other mines used animals, children, women, or miners (in order of increasing expense) to pull rock to the surface. (In many iron mines, which in most cases didn't fall under the "normal" mining laws, women did much of the work.)

The ideal mine, then, was one easily mined near the surface; close to a plentiful source of water for moving ore, ventilation, drainage, and ore dressing; with plentiful fuel for smelting; with an inexpensive source of nearby transportation; and close to the final market for the smelted material. Any mine that didn't have these would be worked harder for a smaller profit.

Let's say that you have a known location of a mineral in friendly territory, that you want to mine it, and that you have a market with a guaranteed price, so that the economic aspect of the mining will be covered. Now it will be simple to get the mine started, right? Not so fast.

Although a mineral location is known in a book or on a map with a scale of 1:2,000,000, that doesn't mean that the mineral will be seen or recognized on the ground. A geologic survey team would need to find the spots for mining the mineral, and find the materials needed to transport the mineral to the market. The current maps also don't show if the mine is a surface mine or an underground mine. Drilling is very expensive, especially if you are not sure that you are drilling in the right place.

Most mineral field guides and rockhound magazines give driving directions to collection locations. They don't show when the mine or quarry was first worked, or even when the road was built. Even when the locations are mines and quarries that existed in the seventeenth century, there is no knowing whether the given mineral formation has been reached yet.

So surveying and prospecting need to be done, and there aren't enough up-timers to do it. Can the up-timers contribute anything? Certainly!

Although the down-timers have lots of experience in surveying a mine site for the economic and political factors, there are some techniques that up-timers know that would be very useful. Up-timers are aware of the chemistry of minerals and the environments in which the rocks formed. Up-timers also use fossils to date rocks over a large area. They know topographic mapping, and geologic mapping. Uptimers have tools for measurement, surveying, and mathematics that can be duplicated. They have worked out simpler methods of determining positions. Up-timers could offer training and tools to the down-timers.

Although the down-timers have lots of experience with minerals, rocks, and mining, they don't have systematic knowledge of minerals. That requires up-timer chemistry. It's no accident that chemistry and mineralogy developed hand in hand. The up-timers know the desired minerals. They could teach down-time prospectors and surveyors how to work with properties such as streak color, hardness, specific gravity, cleavage, and luster. The down-timers know of many of these properties, but not for the new ores.

Down-timers know how to look at the direction of a vein of mineral, and figure the trend and shape of the vein. Up-timers have had much more time to study how rocks are formed. Some geologists study the formation of rocks, figure how the layers of rocks fit together, and where desired resources might be likely to be found. (It would be wrong to say that down-timers don't know this. It's just that this area of exploration has grown by leaps and bounds over the past couple of centuries.) There wouldn't be time for up-timers to teach down-timers dedicated semester-long classes, but up-timer texts could be reproduced.

Up-timers know how to use fossils to determine the age of rocks over a large distance. This is very useful, since similar resources are often found in similar environments.

Topographic mapping and geologic surveying don't exist in the seventeenth century, although accurate surveying on a small to medium scale certainly does. Topographic lines, which connect areas of equal height, give an accurate picture of the lay of the land, all to scale. Geologic surveying throws in the information about the layers of rock in the area. When a geologic map is placed on a topographic map, and information about current mining operations is placed on the map, the result can be an accurate picture of good places to look for desired minerals.

Accurate surveying to scale needs good instruments. The towns of Augsburg and Nuremberg had many makers of fine instruments, including telescopes, and several types of surveying tools, including early theodolites. The surveyors of the time did not have alidades, mountain transits, nor pocket transits like the Brunton compass. (Geologic surveyors in the United States preferred alidades to theodolites, because they were much sturdier and less expensive than theodolites. Civil surveyors might still use theodolites instead.) The instrument makers would have been able to make them, but at a high price. Every instrument out of Nuremberg and Augsburg was a work of art and craft, produced one at a time. Each instrument took a craftsman from several weeks to several months.

The instrument makers did not have access to a circular divider. A circular divider makes it possible to put consistent small regular divisions (such as degrees and minutes) onto a circle. (The inventor of the circular divider shared in the longitude prize given out by the British admiralty, because it allowed the mass production of very accurate surveying and measuring tools.) One of the machine shops should be able to turn out a circular divider, given a short time to create it. From there, accurate surveying tools would be able to be produced much more quickly than the master craftsmen can make them.

Up-timers could also help with mathematical methods of surveying. In the early seventeenth century, there was not a truly accurate measurement for a degree of longitude or a degree of latitude. (In 1637, this and many instructions on more accurate navigation and surveying were due to have been published.) The slide rule had only just been invented, and it wasn't the slide rule we know today.

Eventually, up-timers could even help with mine safety and techniques. The first safety helmets would be made out of hard leather and have oil lamps attached. In time, when kilns and arcs capable of the work came online, calcium carbide and acetylene could be used. The safety helmet might not take long to introduce. Steam-powered ventilation and drainage pumps will take much longer to introduce. The first down-time steam engines will be produced from hand-mined materials, and will be very expensive. It will take a long time until engines and motors are cheap enough for every mine. Cement-lined shafts for areas of wet or loose ground will also take a while to introduce.

There is one mining introduction from up-time that will not always help safety. Underground mining by hand is a slow and tedious business. Underground mining with explosives is much faster, but it is more dangerous. The explosions can loosen rock and make a mine less stable. The up-timers and down-timers will need to work together on handling explosives, and on safety with explosives. In some places, however, the miners set fires underground to crumble the rock, and make it easier to mine. Explosives would be less ghastly to work with than these underground fires.

There's one category of help I haven't mentioned yet. It will probably be the most important, in the short run. Some of the desired minerals (the ores for tungsten, zinc, and nickel, for example) were already known, but were considered junk minerals.

The cheapest route to many mineral resources is to prospect the rubble and slag heaps of existing mines and smelters for desired minerals. Gold is one mineral that can be obtained from slag heaps; another is silver. Down-timers had plenty of experience separating gold and silver from other ores. They did not have experience using cyanide or electrolysis. In order to check slag heaps for desired resources, some method other than straight mineral surveying would need to be used.

Until 1635, Grantville will have a working X-ray spectrometer that will be able to do a nondestructive assay on any samples of slag sent back to it. The X-ray spectrometer is part of the quality and safety equipment at the power plant, and so cannot leave Grantville. After 1635, the spectrometer will not work well enough to give good results, so there is some urgency to the task of getting samples sent from every existing slag heap and rubble pile.

Two types of destructive analysis will take the place of the X-ray spectrometer, eventually. Blowpipe analysis involves holding a piece of stuff in a flame, and blowing a stream of air at it to heat up the flame and the sample. When it's done in a dark room, subtle and unsubtle color changes show what elements are present. The use of a prism, a flame, or an electric arc and a dark room will also reinvent the field of destructive spectroscopy.

Why can't the up-timers just go prospecting? There aren't enough of them, and very few have enough geologic knowledge to do a survey, rather than just prospecting. Grantville is very lucky, as it is a mining town. They have an experienced, German-speaking mining engineer and mine surveyor, two teachers with bachelor's degrees in geology, a quality engineer at the power plant with training in the Xray spectrometer, a civil engineer and surveyor, a few chemistry and math teachers, and several rockhounds. Most towns with thirty-five hundred people just don't have that many people with some experience in geology or surveying.

However, there just aren't enough up-timers. The experienced ones have inescapable responsibilities in or near Grantville. The best they can do is to train others, make tools, and print books.

How would the up-timers teach down-timers about the advances in mineralogy, mining, geolog,y and geologic surveying in a systematic fashion and in a short time? How would they make known the advances in instruments, and train down-timers in their use in short order? The simplest way would be through a field camp for down-timer miners, surveyors, and underground surveyors. Up-timer high-school graduates with a strong background in science and math could also be trained.

Of the first students taking this field course for ten weeks, fewer than half of the experienced miners, engineers, surveyors, and very good high-school graduates would complete it successfully. Learning straight surveying is tough enough. (It's more than a ten-week job.) Good geological surveyors require four skill sets beyond straight surveying. They need to identify the rocks. They need to recognize fossils to help correlate rocks over long distances. They need to picture things in three dimensions, including the boundaries of the layers of rock. Successful students will also need to be people who can work underground without mental problems—even now, it's hard to predict who will be able to work long periods underground.

Today, geology students do much of their learning during field trips. The mother of them all is field camp, an opportunity for them to spend a summer mapping rocks. During field camp, students check their knowledge of several different types of terrain, different types of mapping, and different types of rocks. An extended field camp with a classroom session in the beginning would be the best method for getting the new up-timer information out.

Today, with modern transportation, field camps can range over several hundred miles. In the 1632 universe, any field camp would be limited to within thirty to forty miles of Grantville, for all practical purposes. Fortunately, thanks to the location of the Ring of Fire, there are enough different terrains and rocks to provide a meaningful field camp.

Who would be the students at any field camp? If the first field camp were held in the summer of 1631, the students would be recent female graduates from the high school who were good in math and science. Students would also be engineers, miners, and even some underground surveyors from the mercenary troops and from nearby areas.

In order for the students to work with geared-down surveying techniques, they would need good instruments. Someone would need to make enough instruments for the students to use for field camp, and for successful graduates to purchase after camp. The only way enough instruments could be made would be if an instrument maker were in town. Between the machine shops and the town optician, there is an instrument-making shop in town. However, this would take a lot of time. Fortunately, the optician is married to a geologist turned teacher, so he could be persuaded to spend time on this project. There is a machine shop at the school that might be able to do some of the work over the first summer of 1631.

In order for the mapping to be useful on a large scale, the students would need to be able to locate themselves in time and space. With the help of the alidades, a watch with known slip, and an ephemeris, the students would be able to locate themselves. An ephemeris is a list that gives the rising and setting times for the sun, the moon, the planets, and some bright stars for a given time and place.

The students might be able to locate the geologic time of rocks they were mapping with the help of fossils. Textbooks and fossil field guides have many of the more common, worldwide fossils that help geologists to date layers of rock.

Inside the Ring of Fire, the students would need to learn to use slide rules and refresh themselves on trigonometry, in order to do the necessary calculations for accurate mapping. The first type of mapping they would learn would be topographic mapping. Then they would work on geologic mapping.

Ron Koch, the mining engineer, might be able to spare as many as four mornings to work with the students on mapping the coal mine, allowing them to work and map in the mine on those afternoons.

Any good field camp provides opportunity to work on sedimentary, igneous, and metamorphic rocks. The West Virginian rocks that came through the Ring of Fire are sedimentary. Near Saalfeld (less than ten miles from the Ring of Fire) are some interesting metamorphic quartzites and schists near the Kamsdorf mine, and the Jeramiah's Gluck mine (Feengrotten). If there's time, the students might venture as far as Suhl, about forty miles to the east, to see igneous granites, rhyolites, and andesites, as well the copper mines of nearby Goldlauter.

The only hope for having all the crucial skills in a survey team would be for the team to divide up the tasks. A successful team might consist of an experienced surveyor, an experienced miner, a rodman, and a person dedicated to calculations.

The bad news is that there wouldn't be enough time to teach everything; this would be a crash course. Any survey teams that go out after camp would be serving out apprenticeships in the field. Transportation would be mules or horses—only the down-time surveyors would be used to working with them. Down-time miners and up-time girls (with a couple of exceptions) would have had little experience with horses. Two or three up-time girls may have ridden horses, but would not have used packhorses or pack mules.

The good news is that any field camp near the Ring of Fire would have a wonderful advantage—the Ring of Fire itself. Since it was cut to a molecular level, the Ring of Fire field camp would have the unparalleled advantage of many fresh cliff faces. These cliffs would give an underground glimpse of the geology of both sides of the Ring of Fire. Geologists drool over fresh cliff faces. The Ring of Fire has many fresh cliff faces, of varied height. Instant cross sections! It would be very easy to get across several concepts, just by using the Ring of Fire as a teaching tool.

A field camp such as this is expensive. The cost for teachers, transportation, food, and instruments and gear can be quite high. The town might be able to pay for the first summer's field camp and instruments with good will and high hopes, but any subsequent field camps would need to be attended by paying students. If any students were sponsored, someone other than the taxpayers would need to pick up the tab.

Equipping the surveyors with good instruments of their own (rather than instruments made for the field camp) would also be very expensive. Any instrument sales would need to be paid for by the purchaser—Grantville could not afford to give them away.

No field camp can operate without the permission and cooperation of the existing landowners and mining administration. Fortunately, Duke Johann Philip of Saxe-Altenburg, the landowner and ruler for the mines around Saalfeld, is a forward looking man. He might well be willing to allow a field camp to work on his lands, if he could get the benefit of the best of the final maps and reports. He would certainly be encouraged by the idea of greater mining revenues.

After field camp, the successful students would need to get jobs. Topographic mappers would certainly be in demand by the military—several might even reenter the military. Whether or not others get employment would depend on the various mining administrations and rulers; builders of streets, dams, and canals; as well as the owners of iron and coal mines. Some, such as Gustavus Adolphus, might even pay for students to attend field camp, and assign them to difficult problems immediately on graduation. (That would be how Gustavus Adolphus would have people prospecting for chromite in 1633.) Other areas might show no interest whatsoever in people with this new training.

That's where correspondence would come in. Word-of-mouth advertising was even more important in the seventeenth century than it is today. If employers were happy with the results from their new surveyors, then they would be sure to let others know.

Letters would be important for another reason. Even if all the people who completed field camp in the first two years were offered jobs or went into business for themselves, there still wouldn't be enough people to get samples back from all the slag heaps and rubble piles. The word would need to get out to all mine operators. Only a down-timer who is good at several types of correspondence could do this.

That type of correspondence would really be the start of a formal geologic survey. The government of either the USE or of the Grantville-administered area might want to pick up the tab for a modest geologic survey, but it could not afford to pay for a full survey, complete with many teams.

Grantville would need to take advantage of people who already make public opinion as far as science goes. Geology would need to come into fashion. This isn't far-fetched. In our timeline, geology was a very fashionable science in the first part of the nineteenth century. Correspondence from happy mine administrators, rulers, and landlords to their many acquaintances would be the best possible advertisement for Grantville-trained surveyors. Whether this word would work fast enough to get samples to Grantville before the spectrometer could no longer be used is an open question.

The actual mining and marketing of strategic resources will be carried out mostly by down-timers. One exception might be any mines near Saalfeld. Another would be any easily found petroleum, because of the drilling equipment within the Ring of Fire.

Up-timers can train down-timers in new techniques, and in some cases can be part of down-timer-led teams for geologic and topographic surveying.

Many up-time technologies to make mining more efficient and safe will take a long time to be widespread. Safe lighting and high explosives will spread before engines for drainage and ventilation.

The effort to obtain strategic minerals has the potential to be a strong way to bring together the up-timers and down-timers in economic, educational, and political cooperation.

The fastest way to desired minerals is to survey and work existing mines and slag heaps.

Any eventual formal geologic survey would need a down-timer with superb organizational and political skills as its director. Up-timers will be part of the technical team, but none would immediately have the necessary skills to enable work to be done in multiple jurisdictions.

The 1632 Chem Team. Dr. Manfred Gross and Dr. Virginia Easley DeMarce for assistance with the legal and social structure of mining in the seventeenth century. My son Samuel helped me to make this clearer. All errors are my own.

http://www.wvgs.wvnet.edu/www/allabout/allabout.htm

A Brief history of the WV Geologic Survey:

http://pubs.usgs.gov/circ/c1050/index.htm

A Brief History of the US Geologic Survey:

Pay special attention to the political and scientific skills needed by any successful Geologic Survey Director.

http://region.tu-clausthal.de/obwm/trip.html

A Trip Through Our Mine: The Upper Harz Mining Museum:

An excellent description in English of some of the mining processes used in the Upper Harz mining district. Note the drainage tunnel that took 120 years (with grants of respite) to build, the use of artificial lakes to run the water wheels, and the amount of hard rock tunnel one miner could carve in one year with only iron tools.

Agricola, Georgius. De Re Metallica, Hoover, H. C. and Hoover, L. H., Translators. Dover, 1950. New York.

Much of my information on mining, geology, and mineral knowledge in seventeenth-century Germany comes from the miner's bible of the time, Georgius Agricola's De Re Metallica. Herbert and Lou Henry Hoover published a brilliantly annotated translation of De Re Metallica in 1912. Mrs. Hoover was an excellent Latinist, and had a degree in geology from Stanford. Mr. Hoover was a mining engineer. Both of them had an interest in metallurgy, as well. All later translations into other languages, even German, owe much to the Hoover translation.

De Re Metallica was published in 1556, less than a year after Agricola's death. He had finished the manuscript in 1550, but the elaborate and wonderful woodcuts took a long time to prepare. Even though the novel 1632 takes place eighty years after De Re Metallica was published, mining and refining had not changed greatly in that time.

Geologic map of West Virginia

http://www.wvgs.wvnet.edu/www/geology/geolgeom.htm

Geologic map of Germany

http://www.grosskurth.de/GK%20Deutschland.htm

Poster "Tag des Geotops 2003" (2.7 Mb)

http://www.tag-des-geotops.de/pdf/poster.pdf

General economic geologic map of Thuringia

http://www.tlug-jena.de/contentfrs/fach_09/60_00101_01_a01.html#sm11

These give no detail, but a general idea of what the geology will be in the area. The poster has the best resolution, but is a large file.

Lord, John, Capital and Steam Power. Web reprint in the University of Rochester's Library of Steam

http://www.history.rochester.edu/steam/lord/

A very good review of just how expensive steam engines were during their introduction. Steam will not be this expensive, but it will still be very dear at first. Steam will take a long time to be fully introduced.

The Maps of Mike Barthelemy's 1632 Research Site

http://homepage.mac.com/msb/163x/maps/

Mike Barthelemy's topographic map of the Ring of Fire in Thuringia and Gorg Huff's three-dimensional rendering give a good introduction to reading a topographic map. They also show just where the open cliffs would be located.

USGS Minerals and Mining Yearbook 1998

http://minerals.usgs.gov/minerals/pubs/commodity/myb/

The 1998 version would be the latest version sure to be in the mine office. Many mines do not have a copy of this book, but many do. Quentin Underwood is the kind of manager who would buy a copy every year.

Utrecht's opposition to the Münster peace process

http://www.lwl.org/westfaelischer-friede/wfe-t/wfe-dok.htm

Note the description of mineral profits made during the Thirty Years War.